World Class Gas Project

Kinetiko’s World Class Gas Resource and Plans for Development

Enormous Onshore Gas Resource

World Class Gas Resource in South Africa

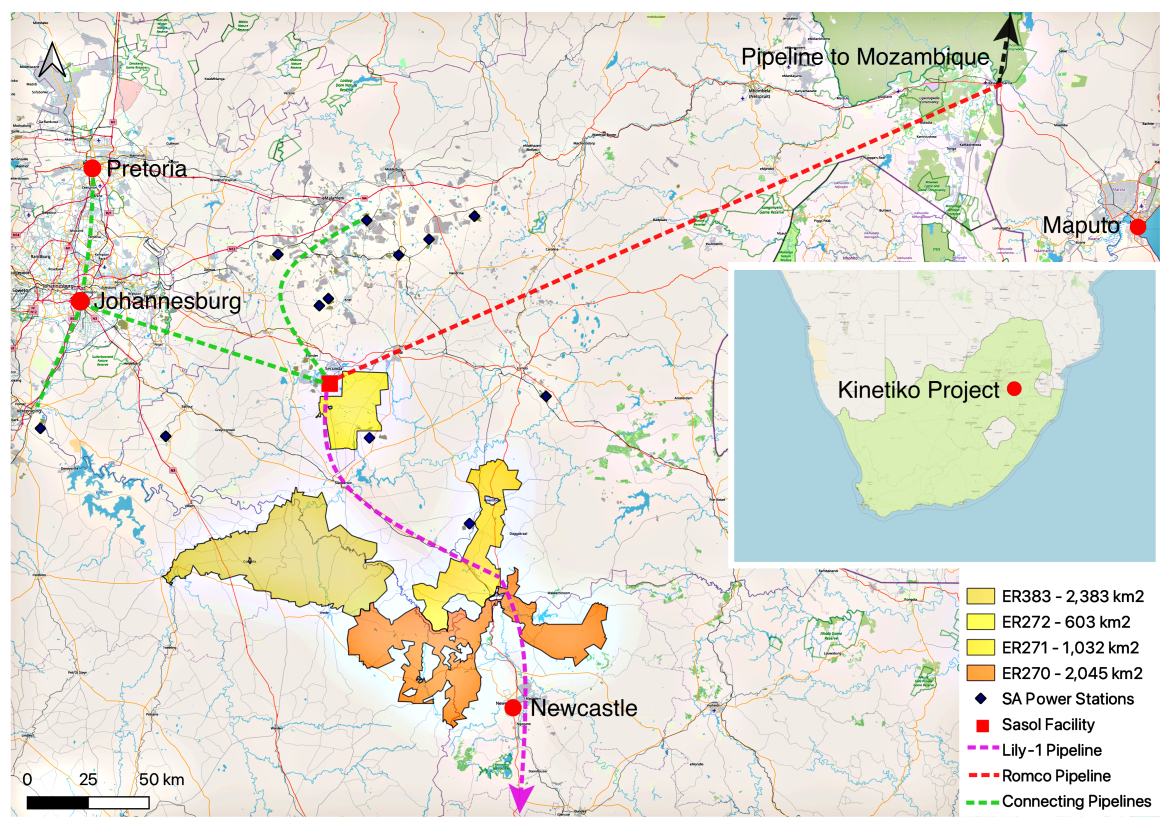

Kinetiko Energy’s gas resource is world-class and in South Africa boasts impressive figures, with a 2C contingent resource estimated at 6.0 trillion cubic feet (TCF) and a 2U prospective resource of 5.8 TCF. The project also a maiden gas reserve certification in late 2023, with 6.4 billion cubic feet (BCF) assessed over a pilot production field, supported by an initial Joint Venture with IDC.

Remarkably, these reserves are based on less than 0.2% of the granted tenements, highlighting the immense potential of the company to continue to grow its gas resources and reserves.

With such substantial resources and strategic partnerships emerging, Kinetiko is positioned to significantly contribute to South Africa’s energy security and economic development.

Kinetiko has received an independent gas reserves and resources report from Sproule B.V. dated 14 August 2023 (“Sproule Report”). The significant highlights from the Sproule Report are:

- Kinetiko’s Net Contingent Gas Resources (2C) of 6.0TCF;

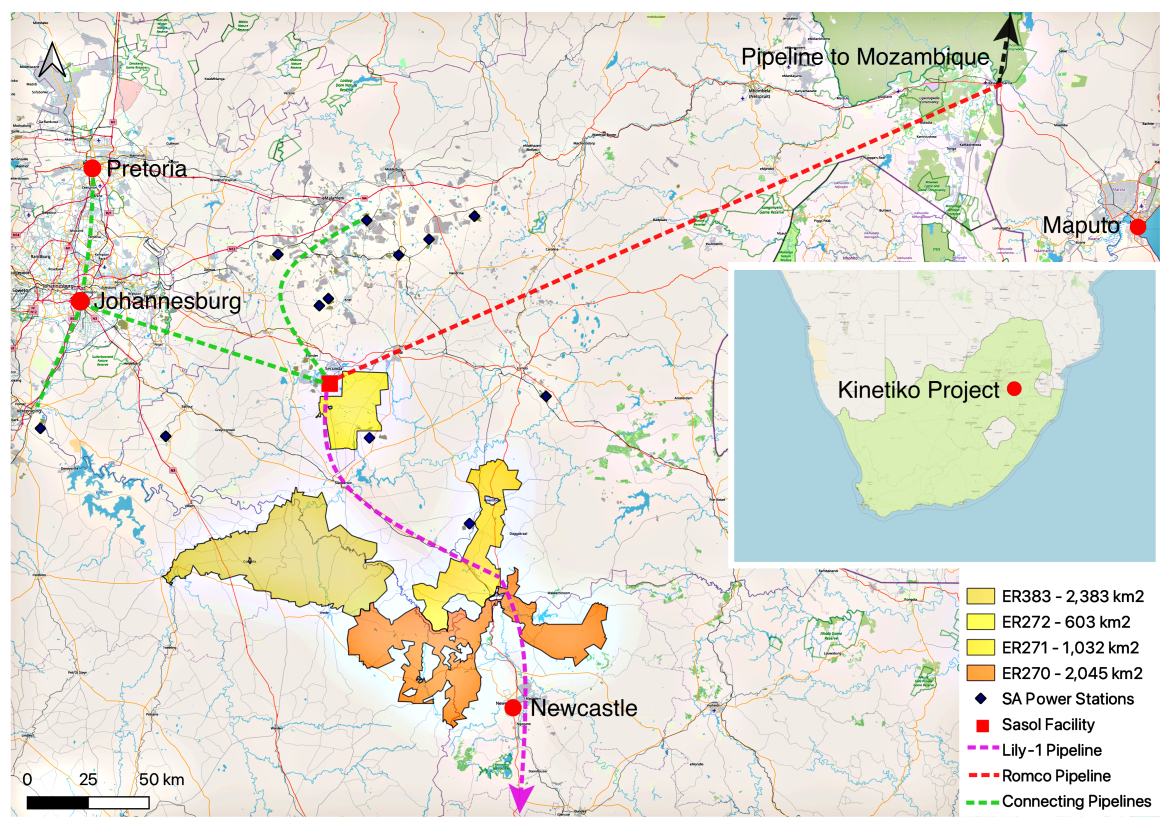

- Maiden gas reserve certification has been assessed over the Company’s planned 30 well pilot production cluster as part of its Industrial Development Corporation of South Africa joint venture (“SPV0 Project”) and calculated to deliver positive economics. The SPV0 Project is to be located in a cluster of wells covering approximately 6.8km2 which forms 0.2% of the granted rights and prospective geology (see figure 1); and

- In addition, 5.8 TCF of Prospective Resources (2U) has been certified on the two exploration rights where exploration work is continuing (ER 270 and ER 272).

Total Contingent Resources Calculated for the Three Kinetiko Licenses (in Bcf, Gross)

Prospective Convectional Resources Calculated for the Three Kinetiko Licenses (in Bcf, Gross)

Kinetiko Energy Project & Infrastructure Map

Development Dynamic & Plan

The Kinetiko Development Roadmap

Step 1: – Drilling to Confirm Gas Field Production Characteristics

- Flow rate and depletion curve testing

- Gas Resource and Reserve Increase

Step 2: – Identify Multiple Optimal Development Sites

- Targeting highest flow rates near pipelines, power stations,

refineries , transmission network to facilitate development sites

Step 3: – Micro-LNG plant proof of concept at Amersfoort

- Drilling additional production holes at existing Amersfoort field

- cluster followed by installation of micro-LNG train

Step 4: – Development of SA’s Largest Onshore LNG project*

- IDC JV – 50MWe growing to 500MWe

- Scale will be hundreds of wells growing to thousands.

- Fiscal Terms: favourable to KKO with IDC providing majority of funding for minority shareholding

The Right Commodity In the Right Place

Our Competitive Advantage in South African Gas

Executing Exploration Excellence

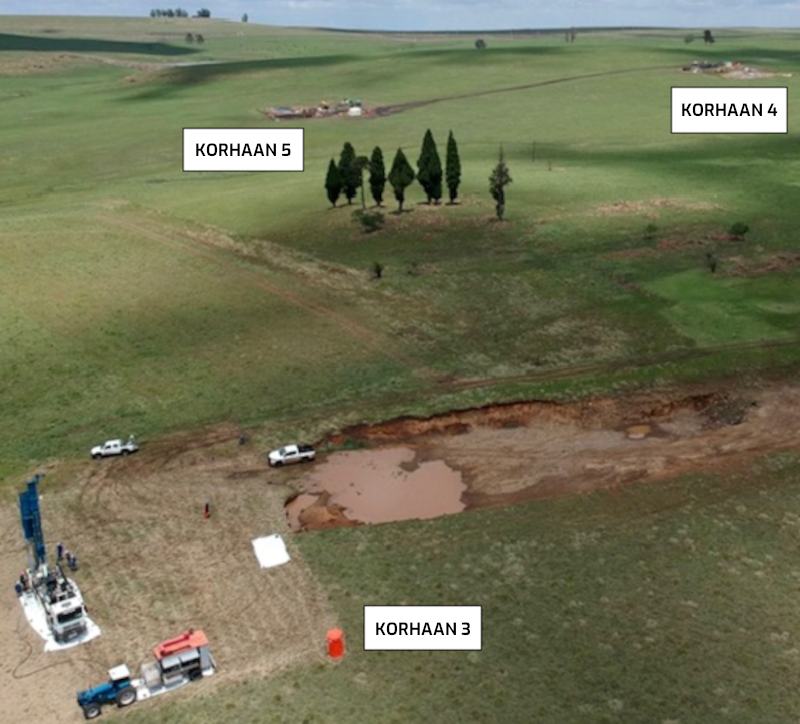

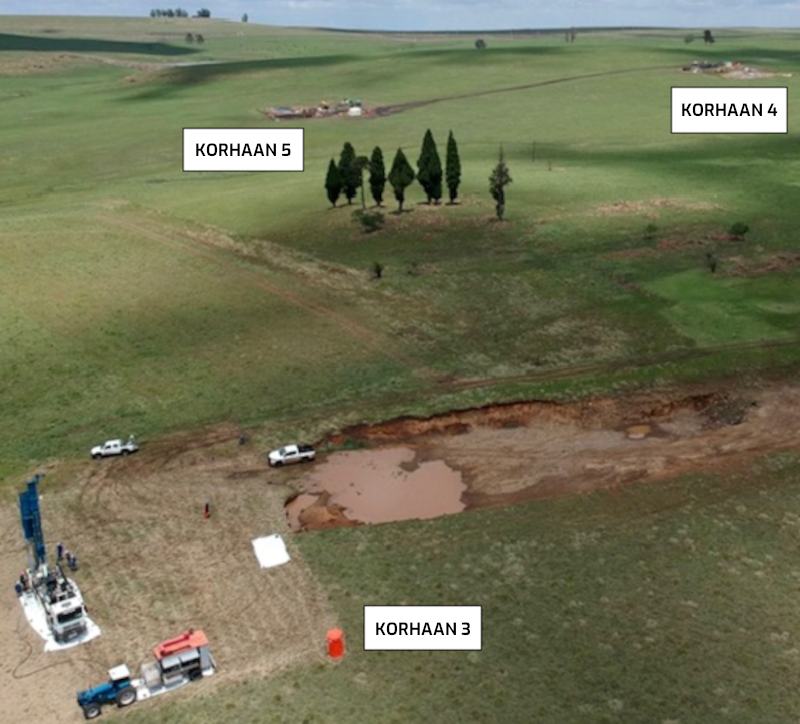

Korhaan Cluster Continues to Deliver

- High resolution gradiometric aeromagnetic surveys completed over three blocks in three phases

- More than 40 core holes drilled with 100% gas strikes

- Several permeability test wells have been completed in ER271 with 100% success:

- Korhaan Cluster consists of five pilot production wells with five more being drilled from late 2024

- Appraisal production wells consisting of five wells in the second half of 2024 will be drilled to assess southern block 271 and northern block 270 flow rate potentials and longevity.

In January 2020 Kinetiko Energy was granted Exploration Rights ER 270,271 and 272 totalling 3,577km2 of tenement.

The average depth of all holes drilled, ranged from 280m to 750m. This is relatively shallow in comparison to other onshore CBM gas fields and shale formations globally. Coal seams identified are between 1M and 4M with cumulative coal measures of up to 25M.

Successful exploration has culminated in significant gas shows in both down hole logging and laboratory canister gas desorption testing.

Through further exploration and the continued successful use of an aeromagnetic survey, the focus will be to continuously expand the gas fairway and to quantify the resource. As further exploration is carried out across our Exploration Rights, we will test both deeper and shallower sediments for their respective productivity.

Development Partnership

Building Government & Regional Partnerships

Kinetiko Energy Ltd has entered into a joint development agreement (“JDA”) with the Industrial Development Corporation of South Africa (“IDC).

The IDC is a wholly owned subsidiary of the South African government mandated to promote economic growth and industrial development in South Africa.

JDA to develop two dozen gas production wells to establish pilot gas production from scalable micro-LNG plants for gas sales to multiple potential customers. The IDC has the option to participate in the increase the gas field by a further 80 wells under the same terms.

The company has applied for a gas production right over all ER 271 to enable first gas sales and revenues in late 2025.

A successful IDC pilot production joint venture program will look to drive a larger IDC Joint venture to develop South Africa’s largest onshore LNG project.